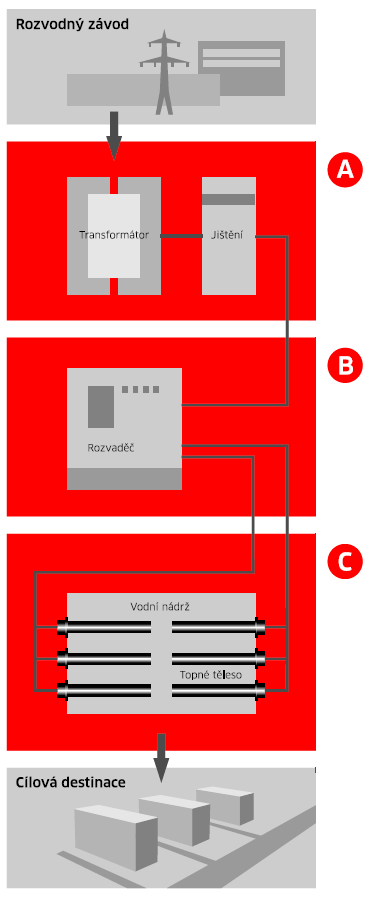

System solution

- can be adapted to specific conditions

- cepending on the circumstances, it is possible to use the entire system or its parts A, B, C independently of each other

High voltage transformation to 3x400V (A)

Distribution transformer 630KVA, 6.3/0.4kV with standard equipment for the transformation of high voltage from the distribution plant to a voltage of 3x400V AC. Securing the secondary side in a separate fuse box. It usually contains a deion circuit breaker with a lever control, there are signaling elements on the cabinet doors. The customer ensures the location of the transformer, its installation and the connection of the primary part to the high-voltage input.

Power and control cabinet (B)

It is used to power electric heating elements and control their temperature. In particular, it contains:

- programmable automat with its own application software that allows you to program and use different work modes, touch control panel on the cabinet door

- the possibility of remote monitoring and control via the Internet

- also semiconductor contactors, fuse disconnectors for individual heating elements, overvoltage protection, cooling, etc.

Heating with electric heaters (C)

- Heaters with an optimized power - dimensions ratio

- resistance to pressure - lifetime - serviceability. The tubular heating element is made of stainless steel, with parameters 3x400V AC, 42,860 W, with a circular flange DN150 PN16.

- The heating assembly then contains such a number of heating elements that the total required power is achieved. This solution has the following advantages:

- individual heating elements can be easily handled during servicing

- logistically, it is only one type of heating element

- in the event of a possible failure of the heating element, it is possible to disconnect only this element - Temperature sensors for temperature control are located outside the heating elements.