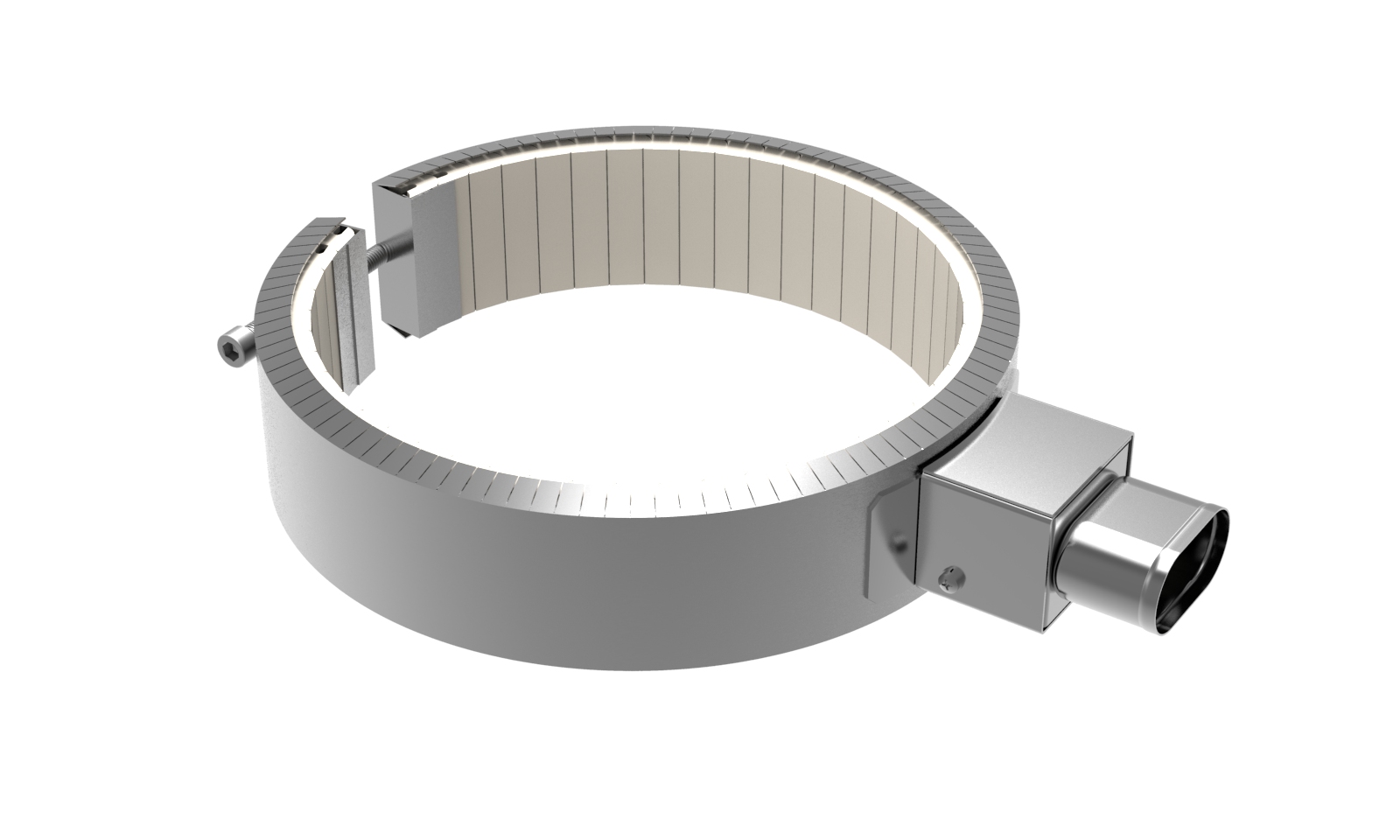

Ceramic band heaters

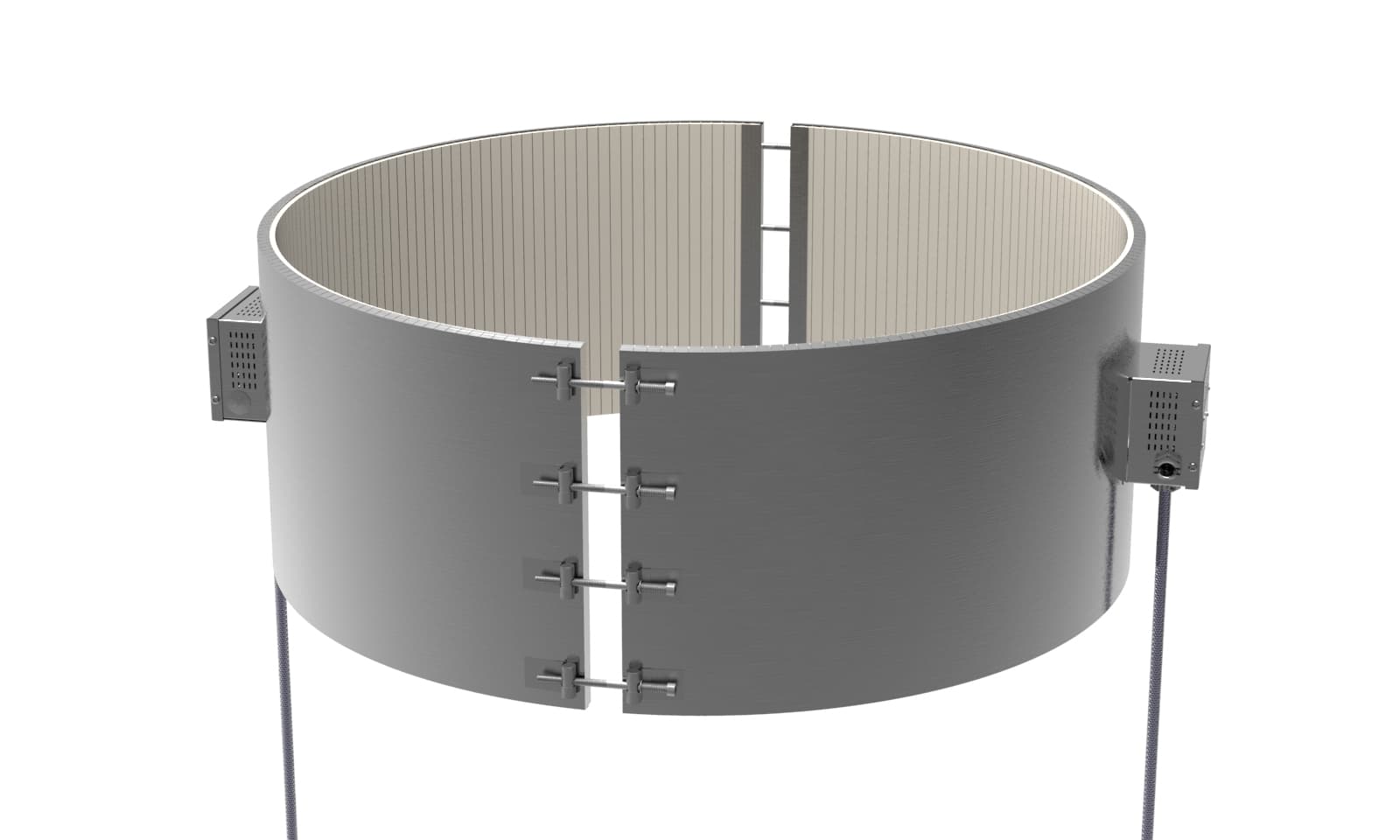

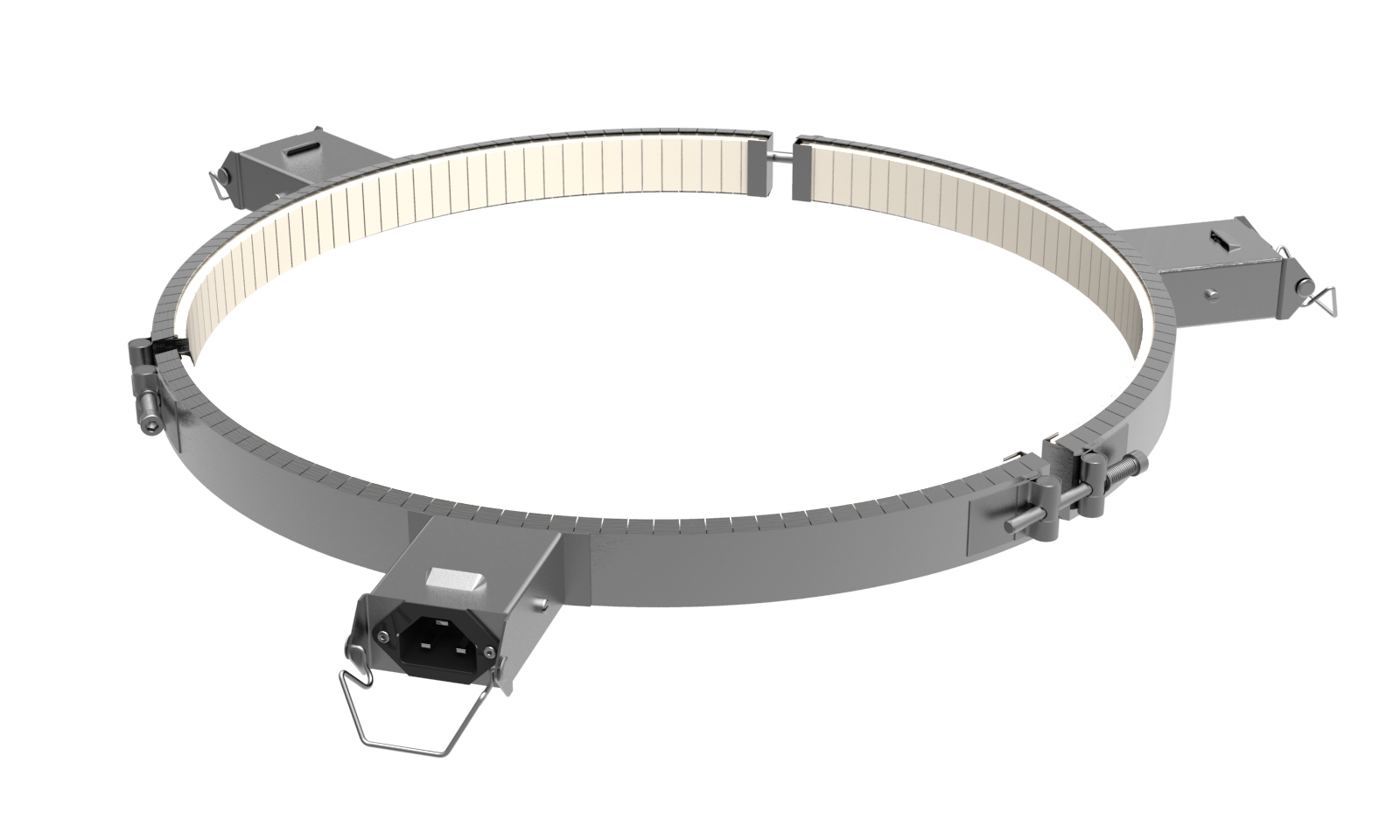

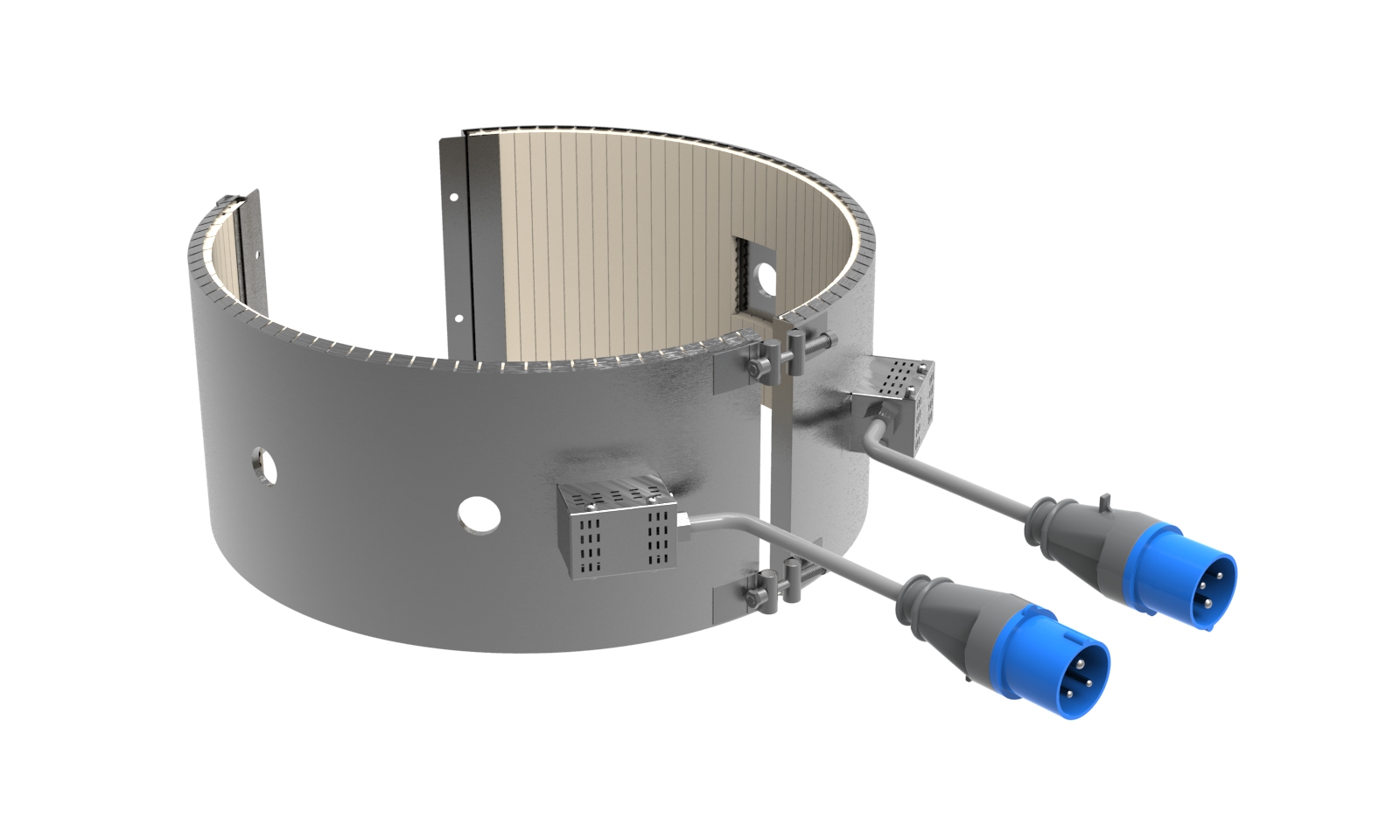

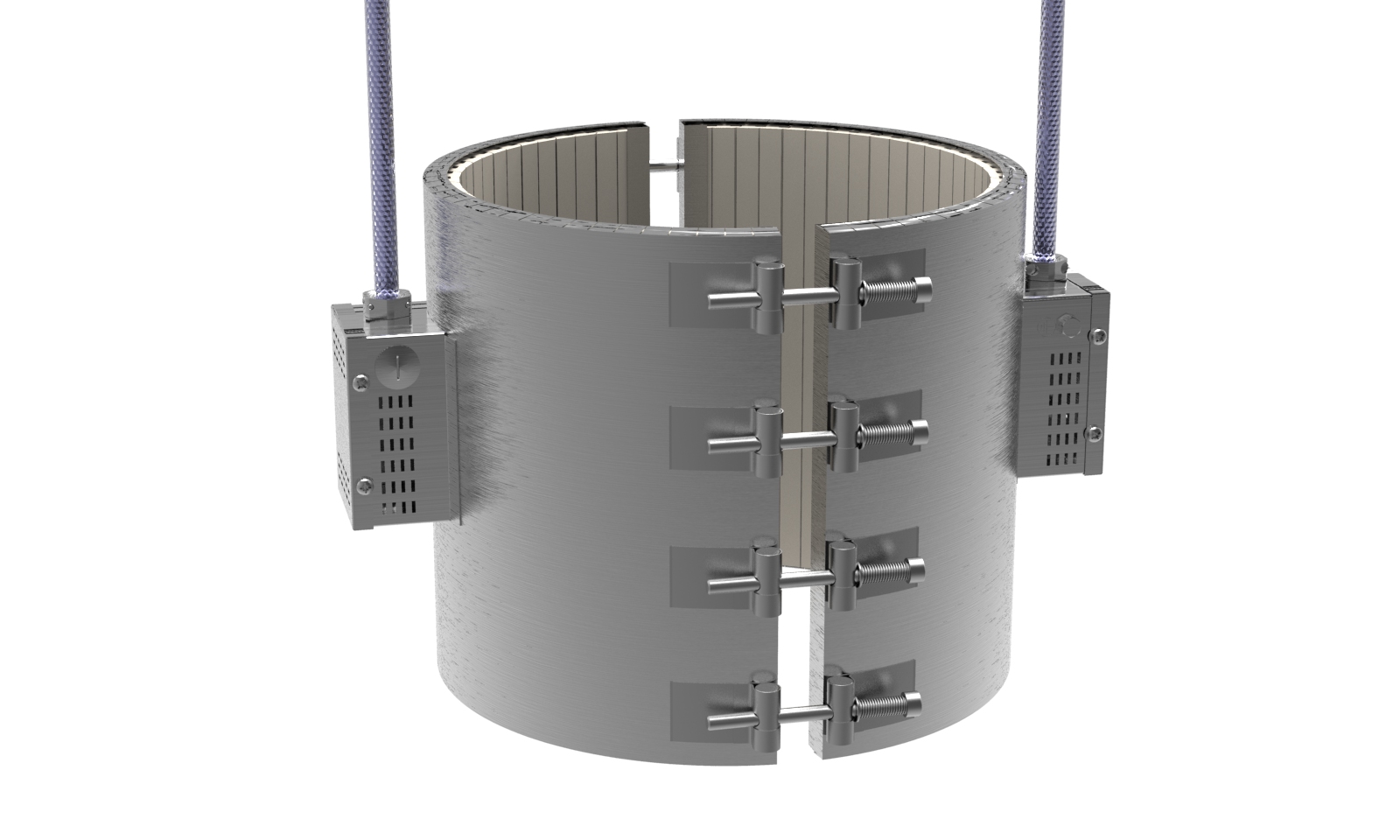

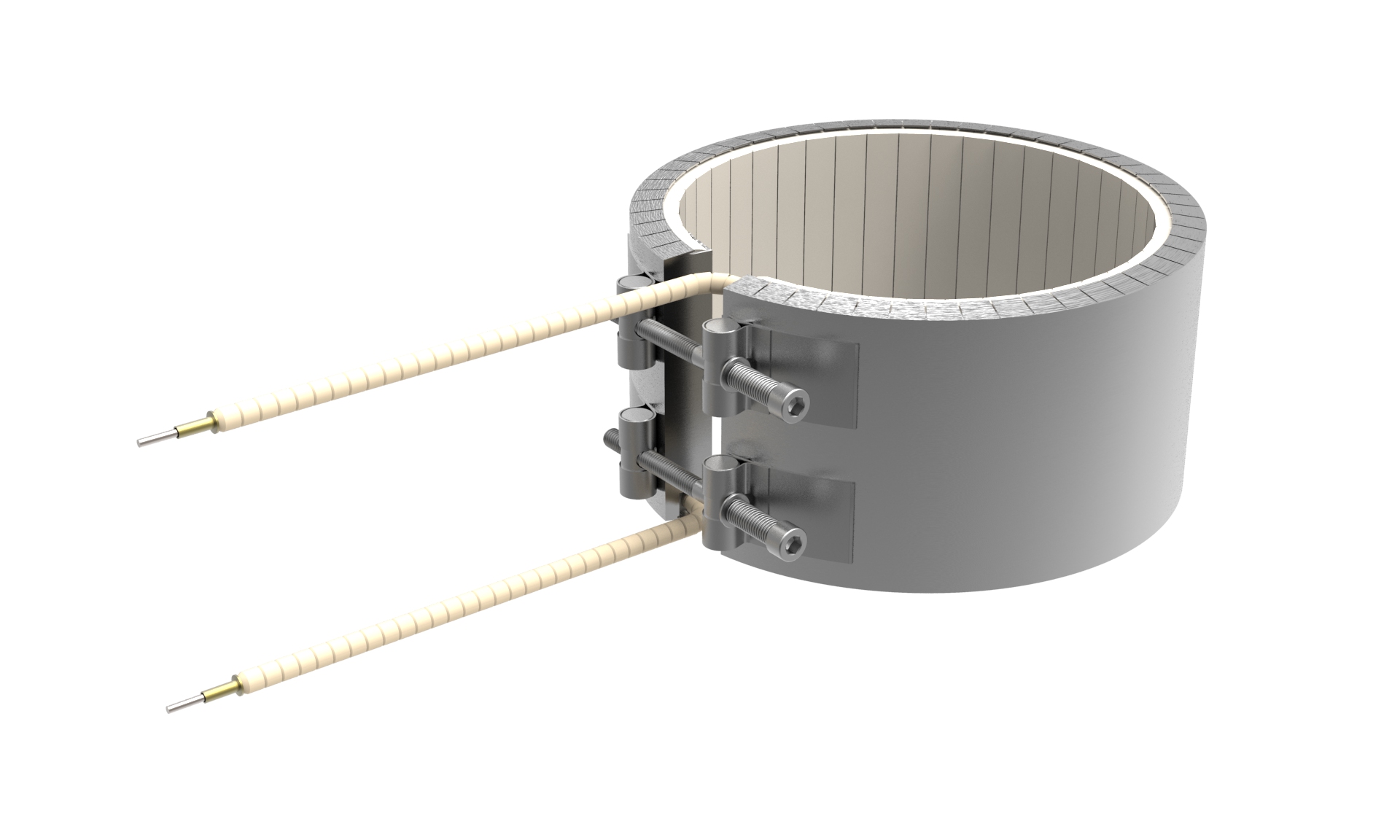

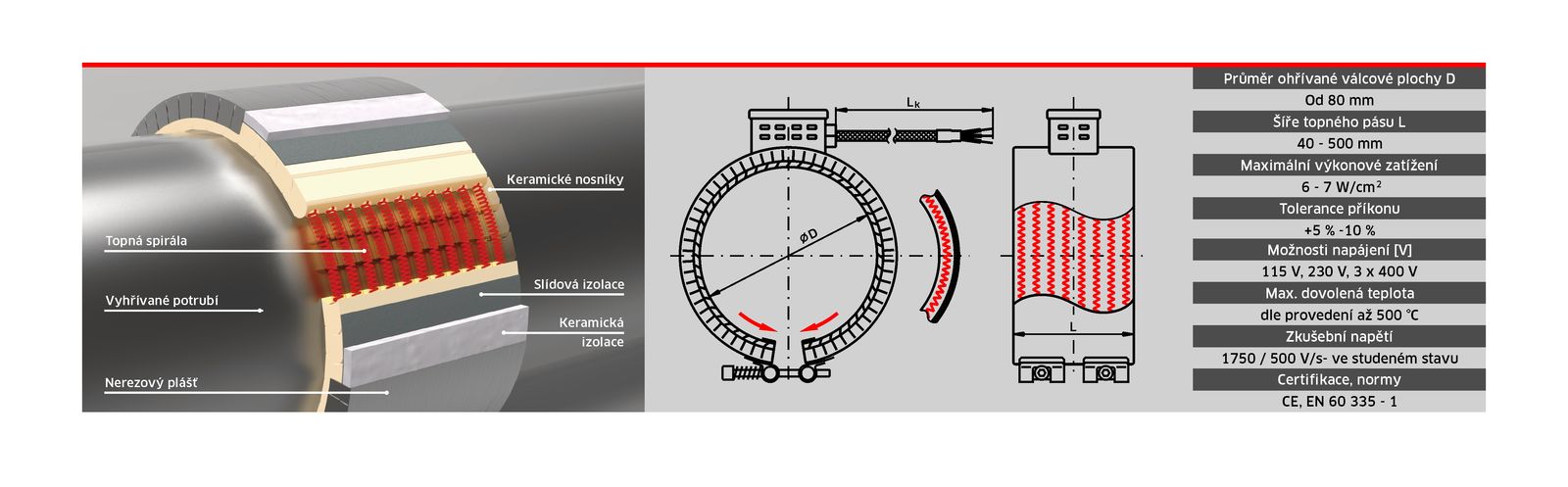

Characteristics and advantages: Ceramic band heaters are capable of transmitting relatively high thermal outputs relative to the built-up area. At the same time, they excel in high mechanical resistance. They can be single-piece or multi-piece, with various power supply options and many shape versions.

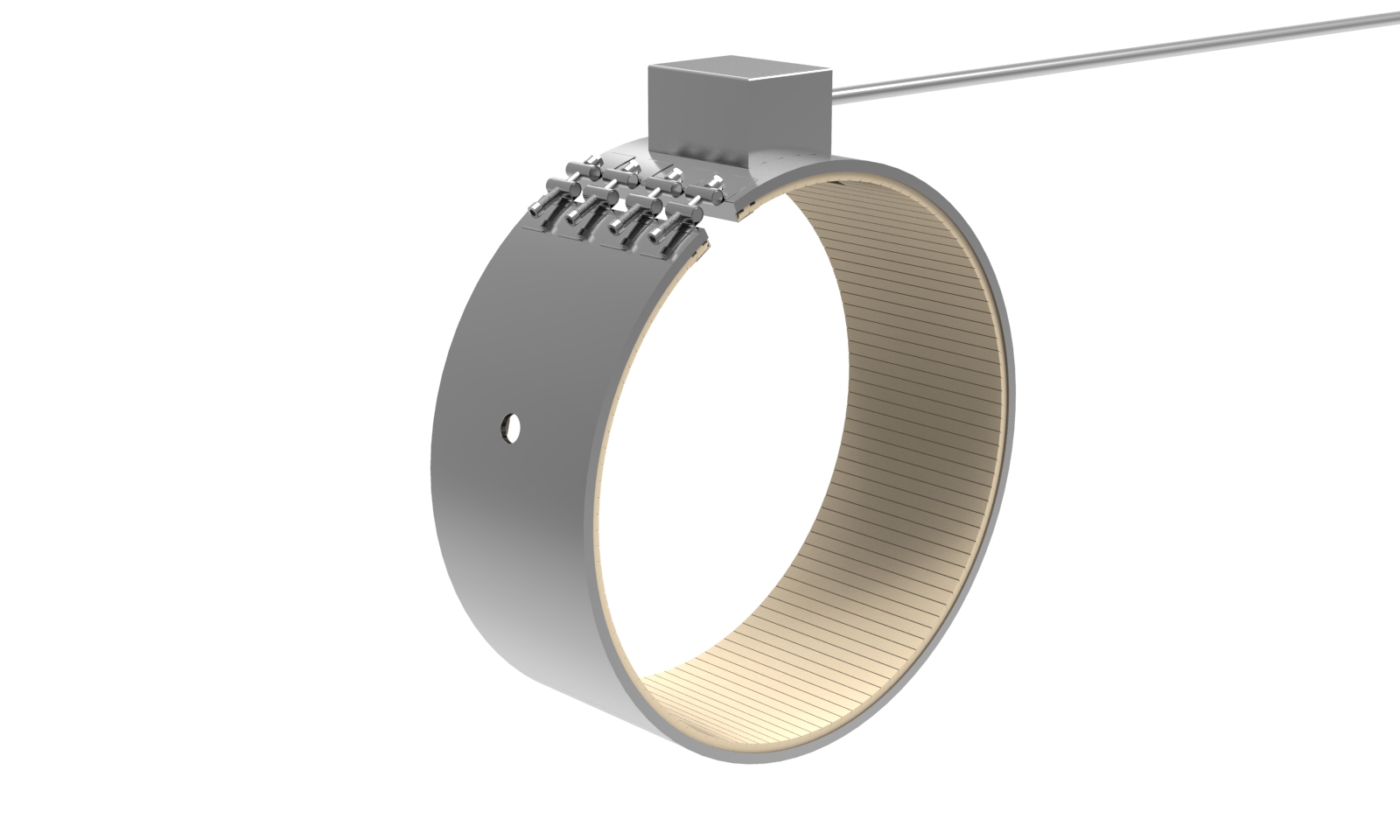

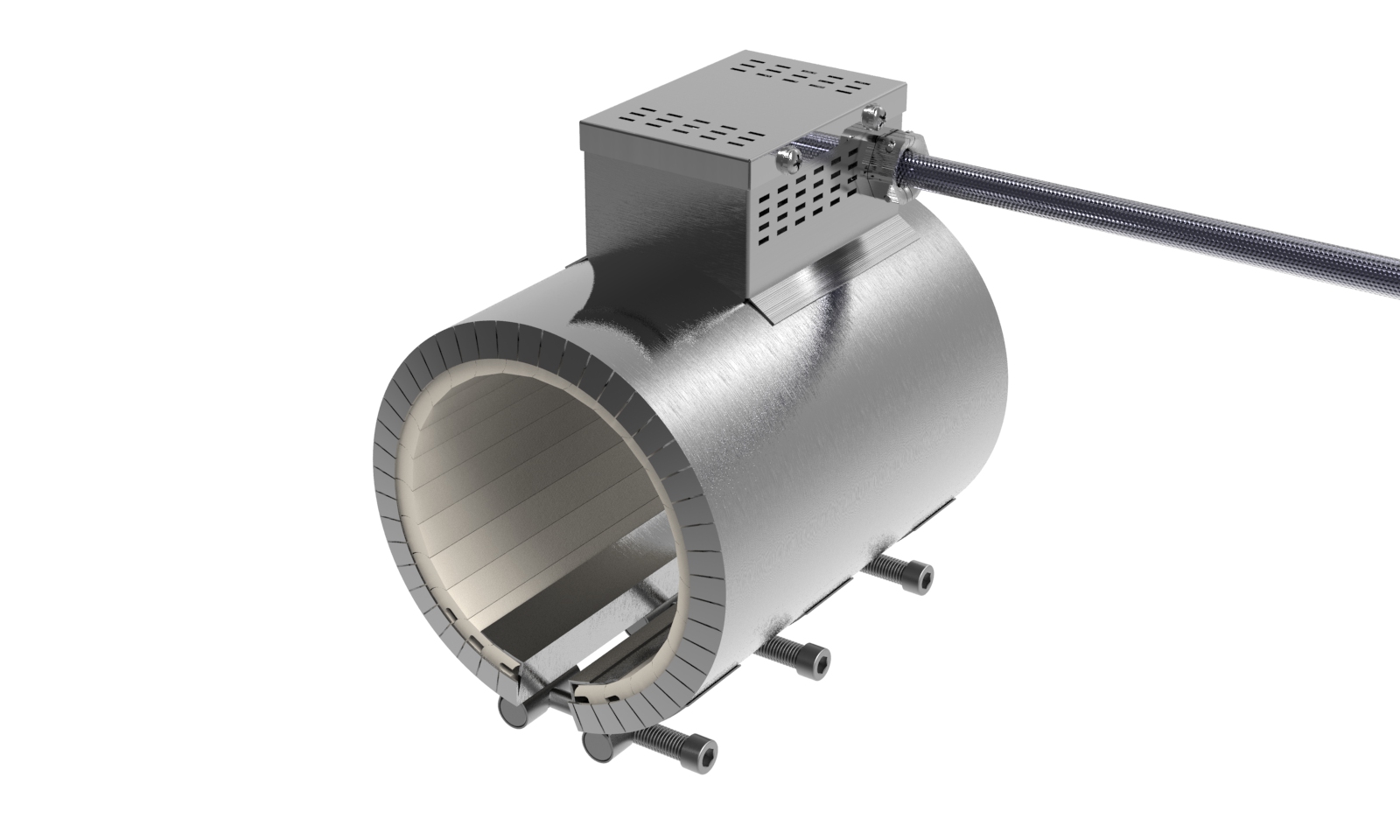

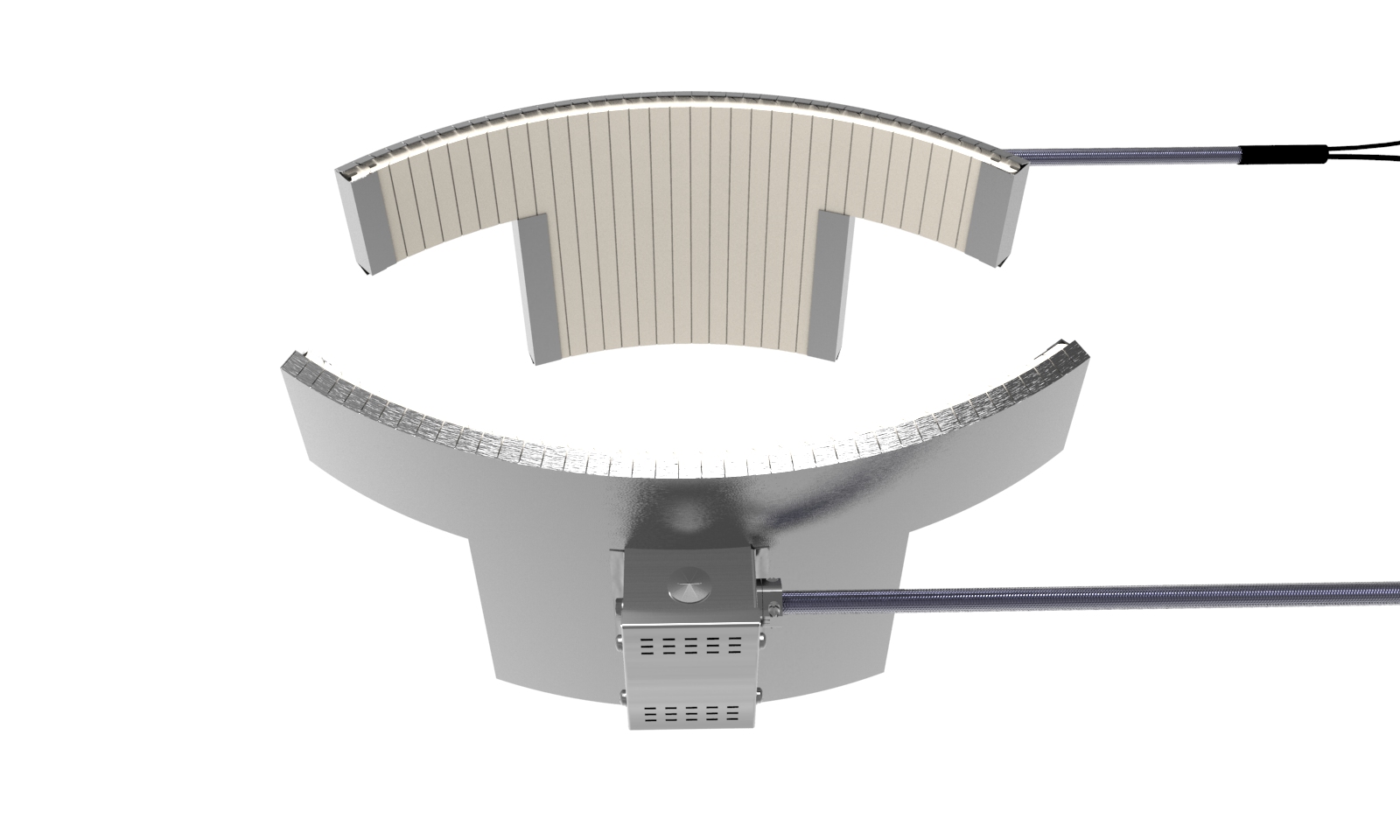

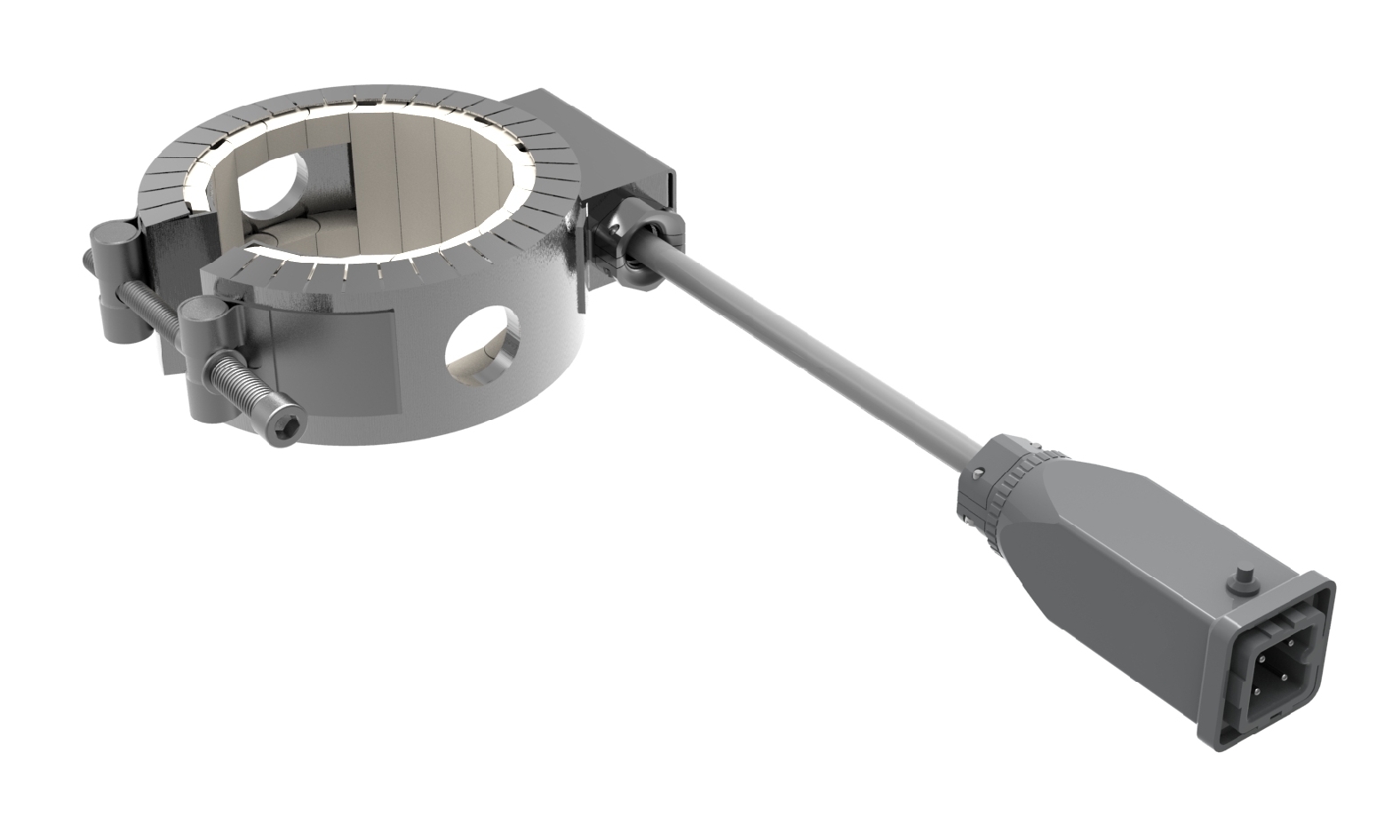

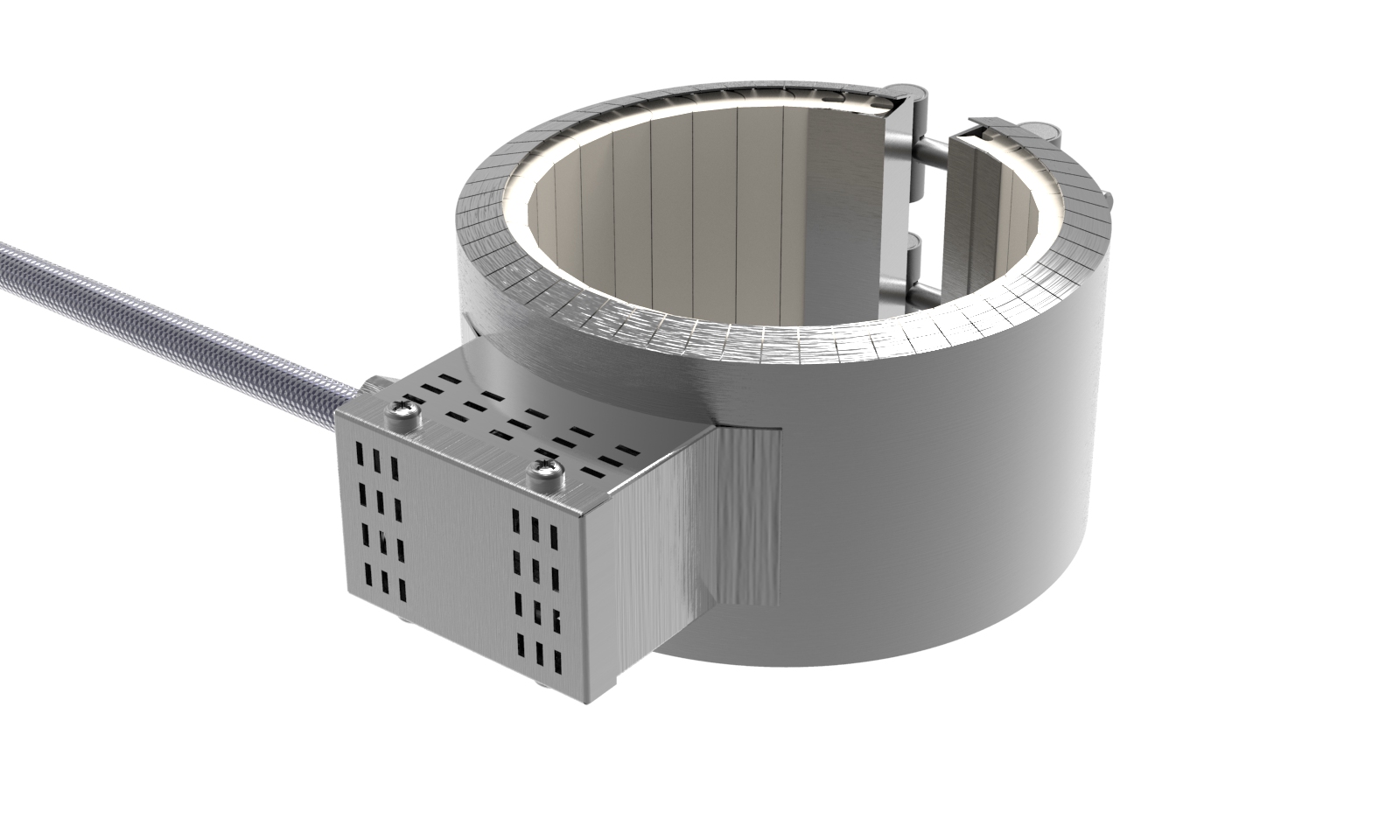

Construction: Ceramic band heaters are made of a ceramic insert consisting of ceramic segments in which a resistance heating spiral is stretched. Technical mica and ceramic wool are used as external insulation. The casing is made of stainless steel sheet. Tightening elements are used to pull the band heater onto the heated surface. A box for electrical connection with a ceramic terminal block inside is mounted on the outer surface of the casing, or there may be a box with a fixed connection of the power wires at the outlet from the heating spiral. Alternatively, wires insulated with glass fabric are led directly from the ceramic insert. The ceramic terminal block in the electrical box must be in the coldest place and must not be at temperatures exceeding +200 ˚C. Ceramic band heaters use cables with a nickel core in a glass textile tube protected by a metal braid with a temperature resistance up to +350 ˚C or if necessary, cable with temperature resistance +450 ˚C.